Miniature pumps, miniature valves & fluidic components for microfluidics

Components and modules with smallest dimensions and highest possible performance.

Description

Use our experience to integrate fluidic components in your microfluidic application. Talk to us at the concept stage of your systems so that we can help you design and select the appropriate components as adequately as possible.

Starting with the design to finished prototypes, we and our partners will fully support you with our knowledge and we are happy to assist you with our manufacturing possibilities.

Please do not hesitate to contact us.

Product overview over systems for research and development

Chip valves & microfluidic chip puzzles

This kit allows you to freely design manifolds by combining valves and flow paths. You can easily create your desired flow diagram in the early stages of development or experimentation.

BMT Software

With the BMT software, many components can be controlled and complex sequences can be programmed. Thanks to the flexibility of the software and the continuous expansion with new features, valves, pumps and sensors for fluidic components can be flexibly combined and controlled. Examples:

- Solenoid valves (monostable & latching)

- Micro-valves with shape memory alloy

- Pumps with DC motor

- Pumps with stepper motor

- Piezo pumps

- Rotary valves

- Micro-jet valves

- Flow sensors

- … and much more …

Learn more about the possibilities in the online manual.

All-In-One Disposable PDMS Chip

Triangular PDMS chips combined into a microfludic system with integrated valves and pumps.<br><br>The pumps can be driven by direct current or stepper motors and both can be controlled with the BMT software like the valves.

Miniature Chip Pump

This system integrates a peristaltic pump into a PDMS chip. The liquid inside the channels of the chip is pumped from the rollers to a peristaltic pump by squeezing the fluidic channels. Only the replaceable PDMS chip gets into contact with the media.

Stepper motor pump controller

- 2 connections

- 0-440mA each port (constant current control)

- up to 1/128 microsteps

- Individual control and programmable using the BMT software

- Can also be used as a stand-alone solution

DC pumps & valve controller

>

- 5 connections

- Flexible connection selection - valve or pump

- 0 - 24VDC each port

- PWM control

- Individual control and programmable using the BMT software

- Can also be used as a stand-alone solution

Piezo pump controller

- up to 4 connections

- Control: 60 - 340Vp-p and up to 60Hz

- Individual control and programmable using the BMT software

- Can also be used as a stand-alone solution

Precise laboratory peristaltic pump with large 7" display

- Speed:0.1 - 100rpm | 300rpm | 600rpm

- CW/CCW

- Speed resolution:0.1rpm resolution (at <100rpm), 1 rpm (at >=100rpm)

- Flow rate:0.15µl/min - 3000ml/min

Multi-channel peristaltic pump BT100-1L

- Precise pumping with up to 24 channels

- Cassette pump heads for tube sets

- Low-pulsation pumping with pump heads with 6 or 10 rollers

High-precision microliter laboratory peristaltic pump - 0.01 rpm resolution

- With precise speed control in 0.01rpm resolution (10000:1 turndown ratio), and flow rate calibration function.

- High accuracy.

- Flow rates: 0,00015ml/min-500ml/min

- Max. Number of Channels: 8

Precise laboratory peristaltic pump up to 3000 ml/min - IP67

- With aluminium alloy housing, the pump has a good corrosive resistance and could be used in corrosive environment.

- With high IP rating (IP 67), the pump could be used in wet and dusty environment.

- Flow rates: 0-3000 ml/min

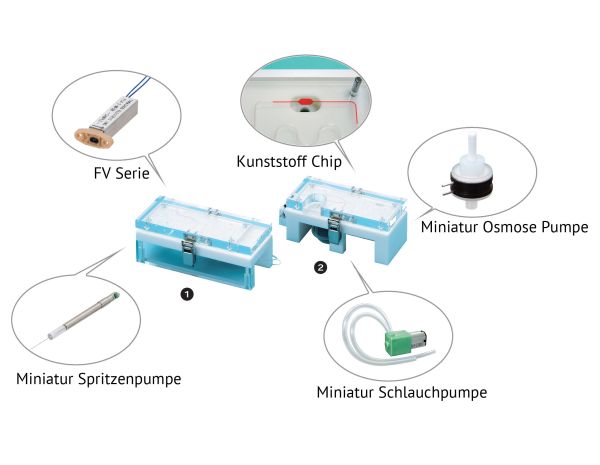

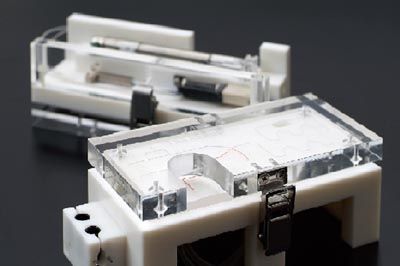

Microfluidic Module 1

In this module, a plastic chip is pre-filled with a reagent.

This module consists of the following components:

- Plastic chip

- Miniature syringe pump

- Ultra miniature solenoid diaphragm-separated valve

Microfluidic Module 2

The basic analysis processes are shown in this module. Starting with injecting the sample, as well as mixing with the reagent until detection. A plastic chip with Y channels is used here. The sample is supplied by a miniature peristaltic pump and is mixed via an electroosmotic pump with the pre-filled reagent. The chip was developed as a disposable chip and can be easily changed at the module.

This module is constructed using the following components:

Microfluidic Module 3

In this module, the supply and mixing of two liquids on a film chip of only 225 µm in thickness is realised. The mixing ratio can be controlled directly by controlling the flanged ultra-miniature solenoid valves.

This module consists of the following components:

- Film Chip

- Ultra miniature diaphragm-separated solenoid valve