Solenoid valves for industry, medical and analytical technology

Electrically controlled valves are available in many different designs for a wide range of areas of responsibility and applications. Controlled by a magnet, various media such as gases or even highly viscous liquids are controlled, mixed or dosed.

Solenoid valves in analytics and medical technology

In analytical and medical technology also aggressive fluids and gases are used, which place high demands on media-contacting materials. Because of the media separation of the valve actuator from the valve body through a separation membrane, the materials coming into contact with the medium can be reduced to durable plastics and elastomers such as PEEK, FFKM and PTFE. For details on the design, see the technical information about diaphragm solenoid valves .

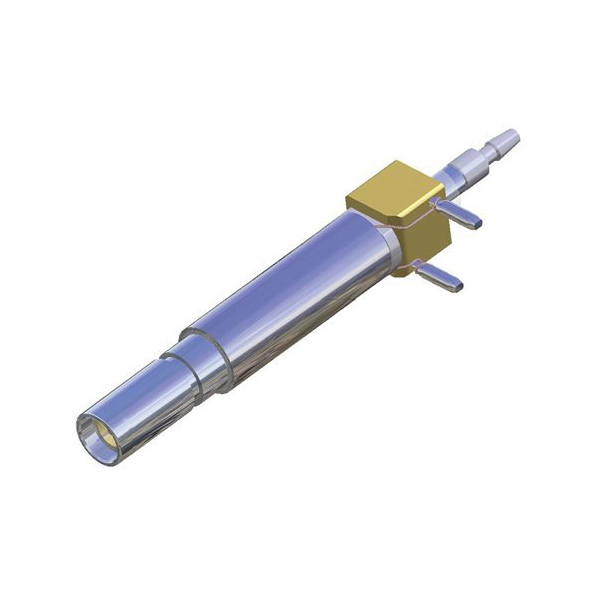

Miniaturization has been a key factor in new developments over the last few years. The media-separated solenoid valves developed for this purpose start with dimensions from 4.2 mm and are also available in a bistable version. For space-saving integration, inline solenoid valves are also available. They allow a straightforwarded and space-saving integration in the fluidic path by inserting a hose on both sides.

For Pinch Valves , only the used hose comes into contact with the fluid, so these valves are particularly suitable for the use with applications in which the media-contacting materials must be replaced after certain intervals. Examples of this are fluidic controls with food or with samples from patients.

Further optimizations and special solutions for specific tasks or applications, for example for environmental analysis, dialysis machines or for sample injection offer interesting solutions that are especially taken into consideration when developing new devices. Through customization, development of individual valve manifolds and integration of miniature pumps and sensors, we offer modules for highly specialized tasks together with our partners. Do you have an application or are you looking for a solution? Contact us !