Micro Pumps for Drug Delivery Systems / Infusion

These micropumps deliver drugs with a very low flow rate. Depending on the requirements, four models with different features are offered. The wetted part, that is exposed to the medication, is replaceable in all models. One of the most important features of the pumps is the provision of a feedback system that uses a flowmeter to measure with an accuracy in the microliter range. This is not only ideal for highly accurate flow control, but also for detecting problems such as blockages or kinks. All pumps can be customized, e.g. if higher flow rates are required.

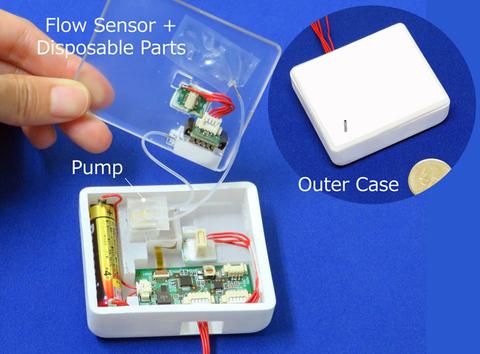

Smart Portable Infusion Pump (Concept)

This is a demo unit showing a portable infusion pump system equipped with our micropump. The flow rate is controlled by a feedback system, while the amount of drug injected is monitored by a disposable microflow sensor.

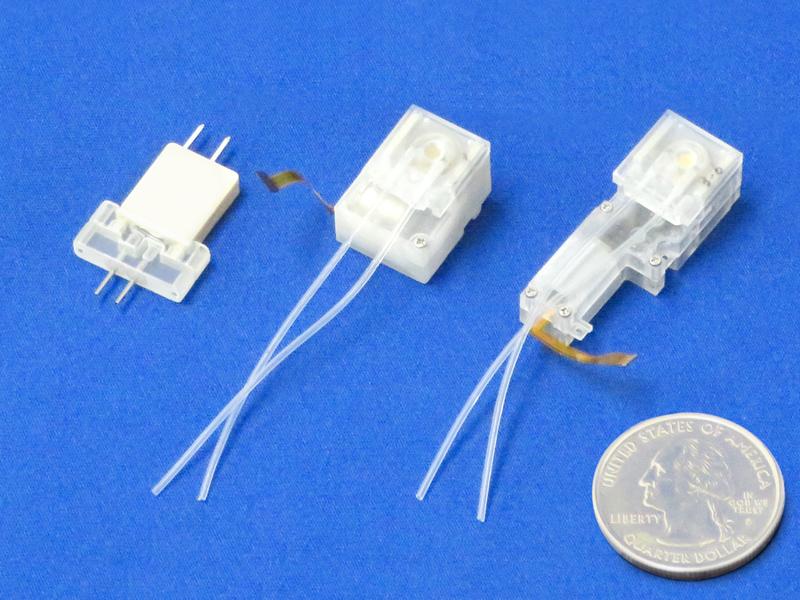

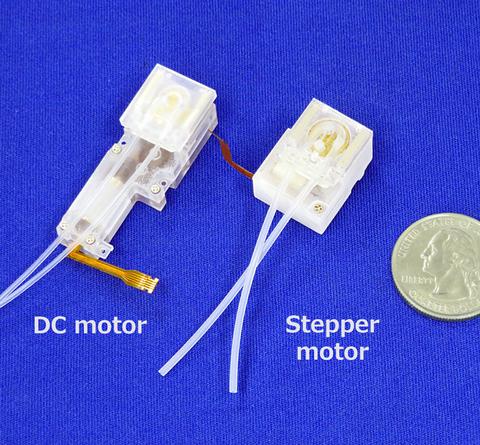

Chip-Pumps

In contrast to peristaltic pumps, the tube of this pump is integrated in a magnetic chip, so that it can easily be attached to the motor and detached again. This makes the exchange of the tube very easy.

The pump is optionally available with a stepper motor for high-precision flow control or awith a DC motor that uses less power. When the motor stops, the tube is closed by the rollers, so that there is no free flow (there are no leaks due to pressure differences).

Information on these pumps can also be found in the product categories:

Piezoelectric Diaphragm Pumps (Piezo Pumps)

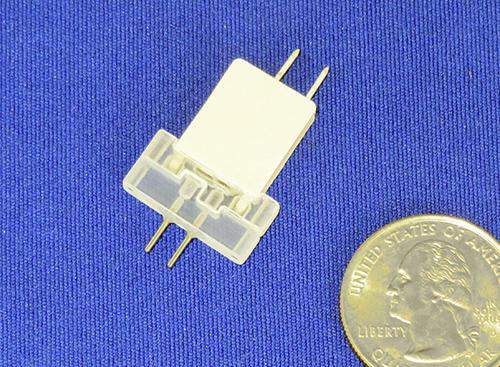

The wetted part is attached to the piezoelectric drive unit by a magnet and can be easily replaced. The replaceable part in the picture is only 6.9 mm thick and weighs 13 g. Because the flow rate can be precisly adjusted by the voltage and the frequency, the piezo pump is ideal for feedback control.The wetted part is attached to the piezoelectric drive unit by a magnet and can be easily replaced. The replaceable part in the picture is only 6.9 mm thick and weighs 13 g. Because the flow rate can be precisly adjusted by the voltage and the frequency, the piezo pump is ideal for feedback control.

More about the Cartridge type piezoelectric diaphragm pumps (Piezo Pumps).

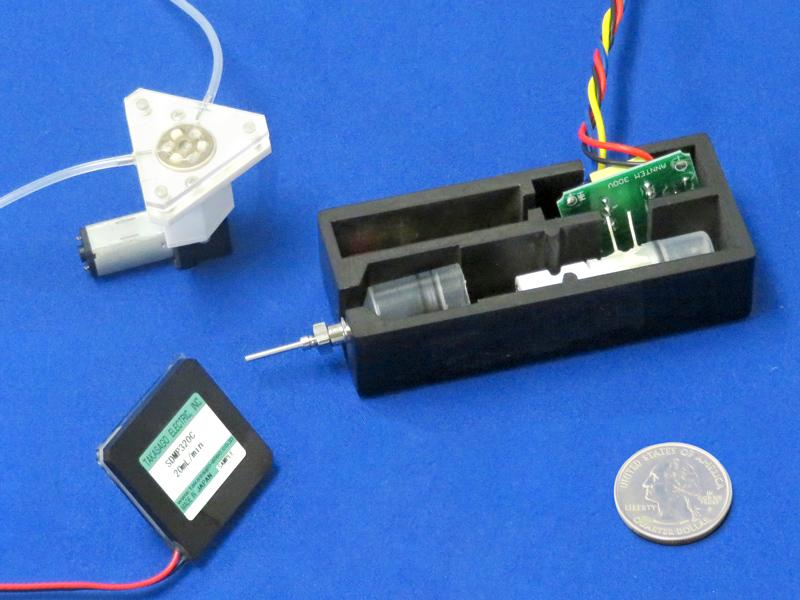

Electro-osmotic Flow Driven Micro Syringe Pump

This product uses a pump called “electro-osmotic pump” for the drive unit. It delivers drugs, stored in a microsyringe, very slowly and without pulsation. Due to the very low power consumption, a small battery can be used. One of the features of this electro-osmotic syringe pump is that it can inject a drug at a higher pressure than other pumps.

Here you will find general information about the syringe drive and the electro-osmotic pumps.

Shape Memory Alloy Pump

This is a pump that delivers approximately 0.9 μL of liquid per stroke, by shrinking a shape memory alloy wire. This makes it the most economical pump of all four models, as it does not use a motor or other more expensive actuators. The pump is designed as a disposable pump and should therefore be replaced after each use. The injected amount is controlled by the number of strokes. The pump in the picture is 4 mm high and weighs only 1.7 g. There is no free flow with this pump.

More about the miniature dosing pumps with shape memory alloy actuator.