Protection of Sensitive Differential Pressure Sensors in the Aerospace Team Graz Pitot-Static System with BMT Inline Solenoid Valves

Project Context

As part of the research project by the Aerospace Team Graz, a Pitot-static system is being developed to test the accuracy of barometric speed and altitude measurements under extreme conditions. Measurements are taken using absolute pressure sensors for static and dynamic pressure, as well as additional differential pressure sensors with a small measuring range to increase precision at low speeds.

Challenge

- The differential pressure sensors are sensitive to overpressure, which can occur at high flight speeds.

- Overpressure would damage the sensors and impair measurement accuracy.

- The available space at the tip of the rocket is very limited, requiring a compact solution.

Solution

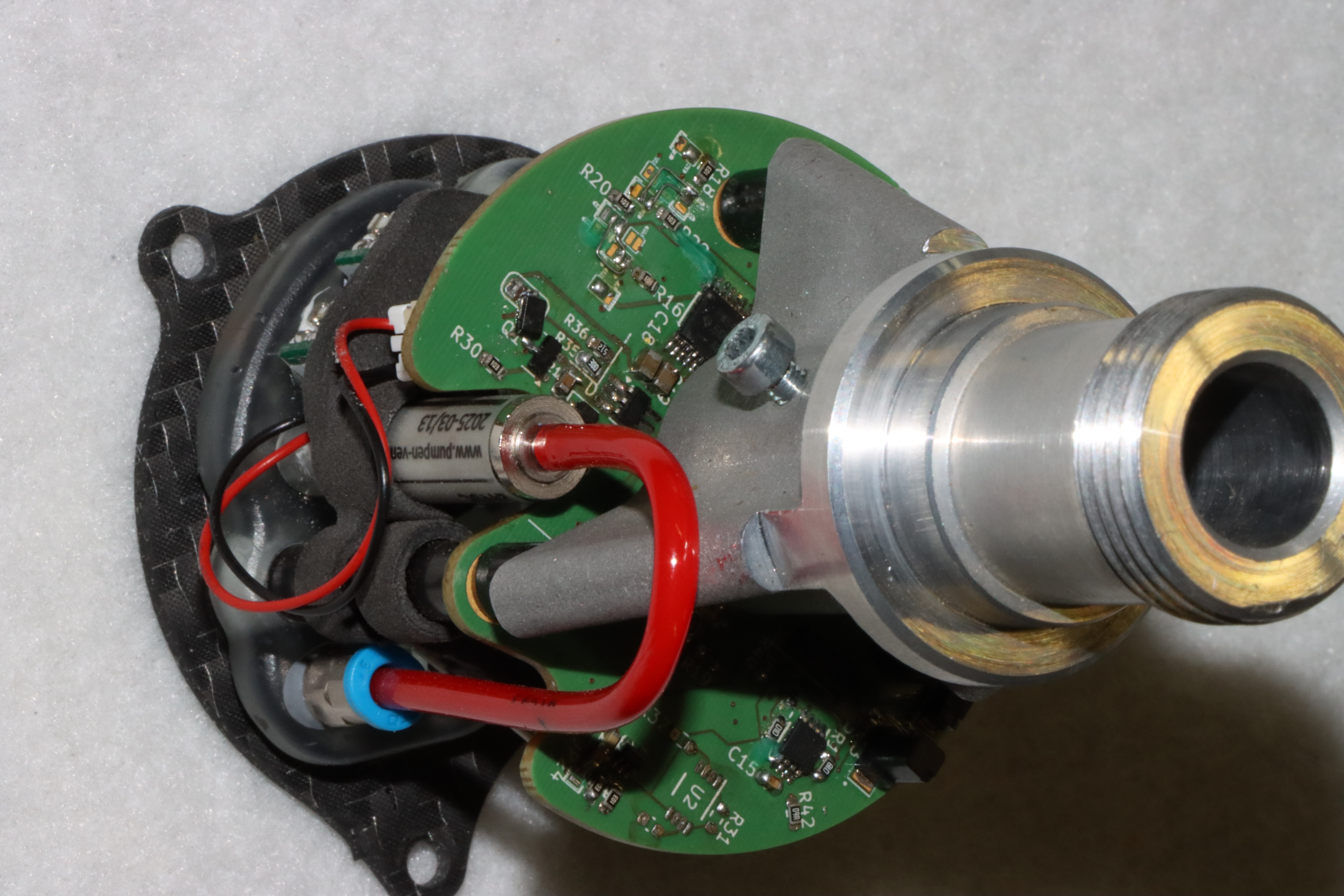

To prevent overpressure damage, a BMT inline solenoid valve (7.5 mm) was integrated into the PSP manifold. This valve enables:

- Shutting off the pressure path at high speeds to protect the sensitive sensor.

- Fast and precise control of pressure flow due to its compact design.

- Minimal space requirements, which is crucial for integration into the tapered shell of the rocket tip.

Technical Advantages of the BMT Valve

- Compact design (only 7.5 mm) for tight installation spaces.

- Axial flow guidance for low pressure loss.

- High reliability under extreme conditions (vibration, temperature changes, vacuum).

- Low power consumption, ideal for energy-limited systems in space.

Result

By using the BMT inline solenoid valve, a highly precise and compact measuring unit was realized that:

- Ensures the operation of the differential pressure sensors within their optimal measurement range.

- Extends the lifespan of the sensors by protecting them from overpressure.

- Meets the requirements for weight and installation space.