AMV-EVN-24-01 Miniature Valves in Space Use – PERSIS Project

Application: Additive Manufacturing of Structural Components in Space

Product Used: AMV-EVN-24-01 Axial Miniature Valve

Client: PERSIS – an interdisciplinary student project at the Munich University of Applied Sciences and the Technical University of Munich

Initial Situation: The PERSIS team developed an experiment for use on board a sounding rocket as part of the REXUS/BEXUS program. The goal of the project was to manufacture carbon fiber-reinforced structural components under space conditions.

For this purpose, a photopolymer resin was to be precisely dosed and cured under UV light – an innovative step towards additive manufacturing in space. Compact, reliable miniature valves were required to precisely control the resin flow and operate reliably even under extreme conditions.

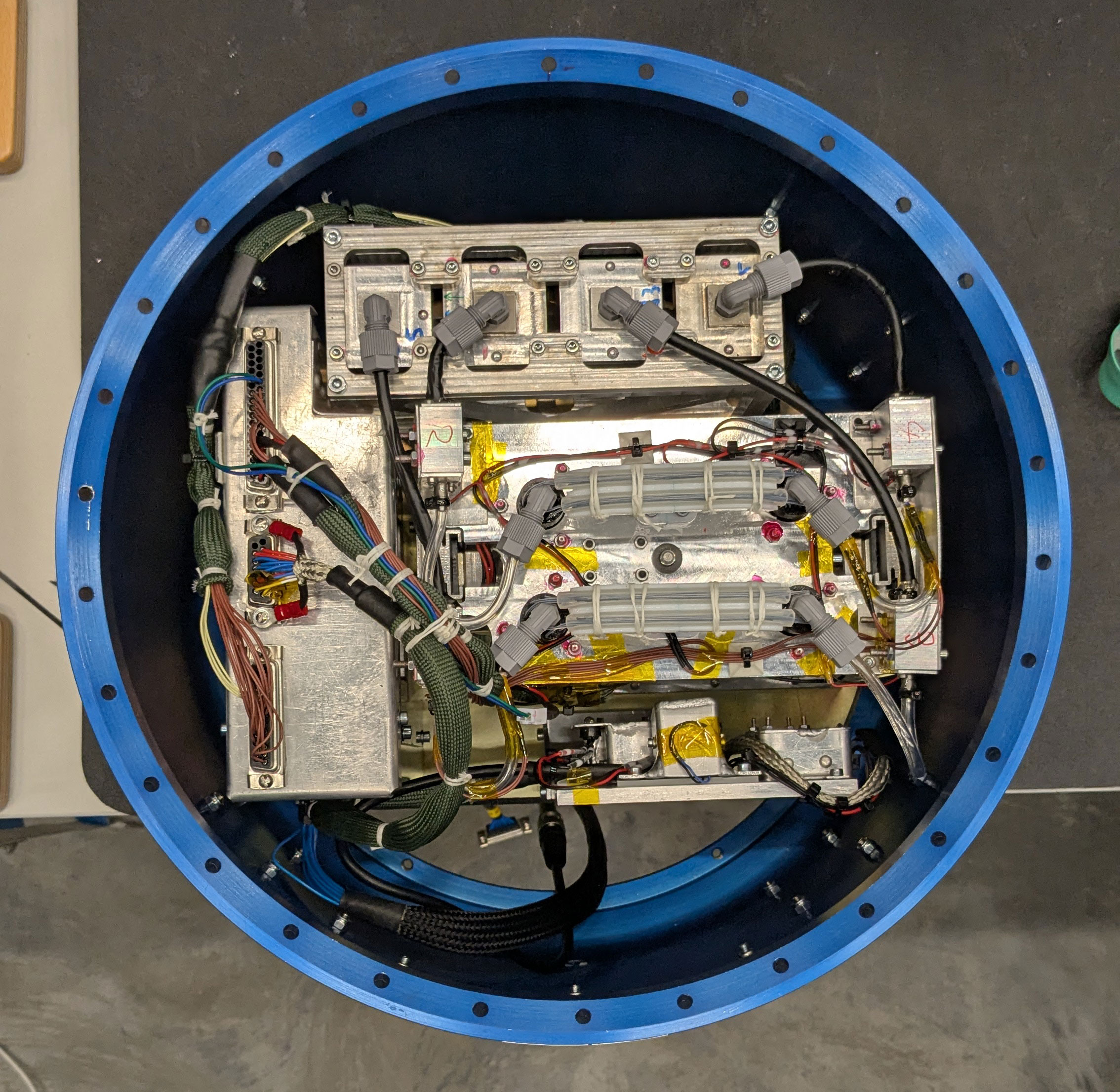

During the preparations, we supported the team with several valves. To cope with the thermal stresses during rocket flight, the team constructed special housings for heat dissipation – visible in project photos.

The Result

The rocket launch took place on March 11, 2025 – with complete success:

The experiment worked as planned. Four of our AMV-EVN-24-01 valves were used on board – they opened and closed as intended, enabling successful resin flow for component manufacturing.

The PERSIS team's conclusion:

"Your valves worked great! We had four valves on board, and all of them opened and closed as planned."